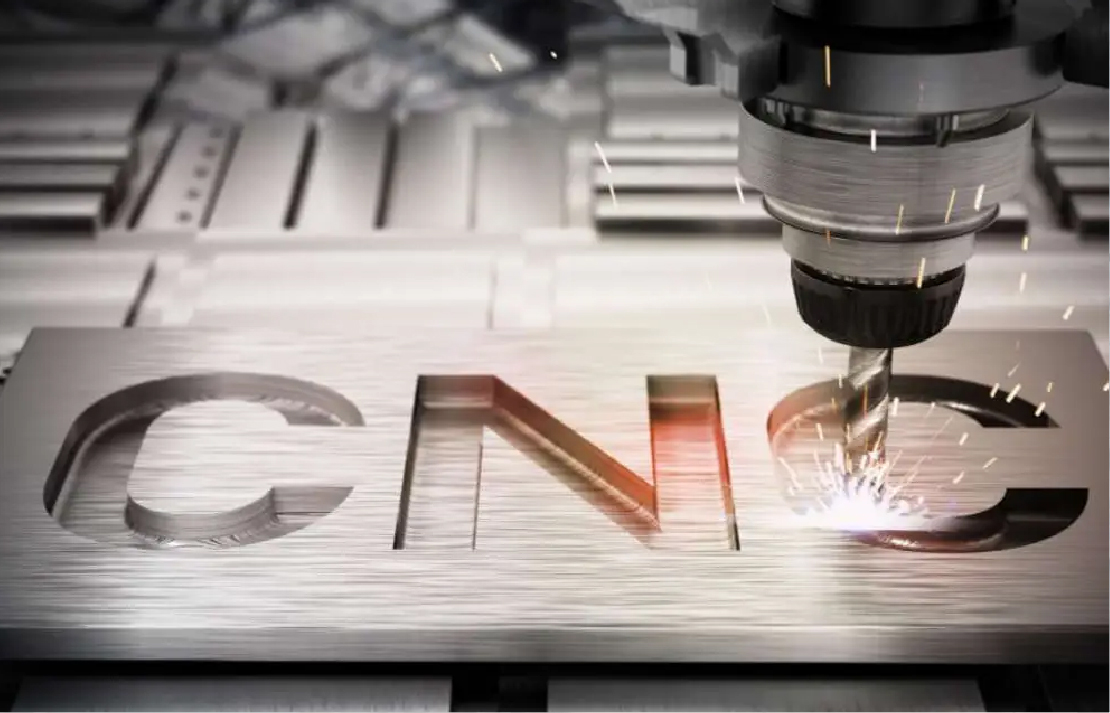

High precision and repeatability

CNC milling machines use computer control to accurately perform complex machining procedures, ensuring that the size and shape of each product fully meets the design requirements.

This high precision and repeatability is particularly suitable for the production of demanding electronic and optical components.

High degree of automation

CNC milling machine processing is a highly automated process that can run continuously for long periods of time without human intervention.

This greatly improves production efficiency, reduces labor costs, and reduces the risk of human error.

Flexibility and versatility

CNC milling machines are capable of processing a variety of materials, including metals, plastics, wood, and composites, and can perform a variety of different machining operations such as drilling, cutting, milling, and more.

This makes it widely used in different industries such as the production of automation equipment parts and aerospace components.

Fast processing speed and consistent quality

CNC milling machine processing can complete multiple steps at one time, and the processing speed is fast, thus greatly shortening the production cycle, especially when mass production is required, it can significantly improve production efficiency.

CNC milling machine processing can ensure consistent quality of each product, which is very important for industries that require high quality control, such as optical components and aerospace components.

Integration of design and manufacturing

With CNC milling machines, the design and manufacturing processes can be better integrated. Designers can directly convert design files into processing instructions, reducing the gap between design and production and improving work efficiency and product quality.

Reduce waste

CNC milling machine processing can accurately control the amount of material used, reduce waste, and thus reduce production costs. At the same time, optimized machining paths can also extend tool life.

CNC milling machine processing

CNCMilling It has several advantages that make it an indispensable processing technology in many industries.

Combining the above advantages

CNC milling machine processing technology not only improves production efficiency and product quality,

but also brings significant economic benefits and competitive advantages to enterprises.

Yongyi Technology can rely on its twenty years of professional experience to provide high-quality CNC

milling machine processing services for multiple industries,

This is an important factor in its foothold in the market.

Twenty years of professionalism Processing experience

VIEW MOREAdvanced CNC processing equipment

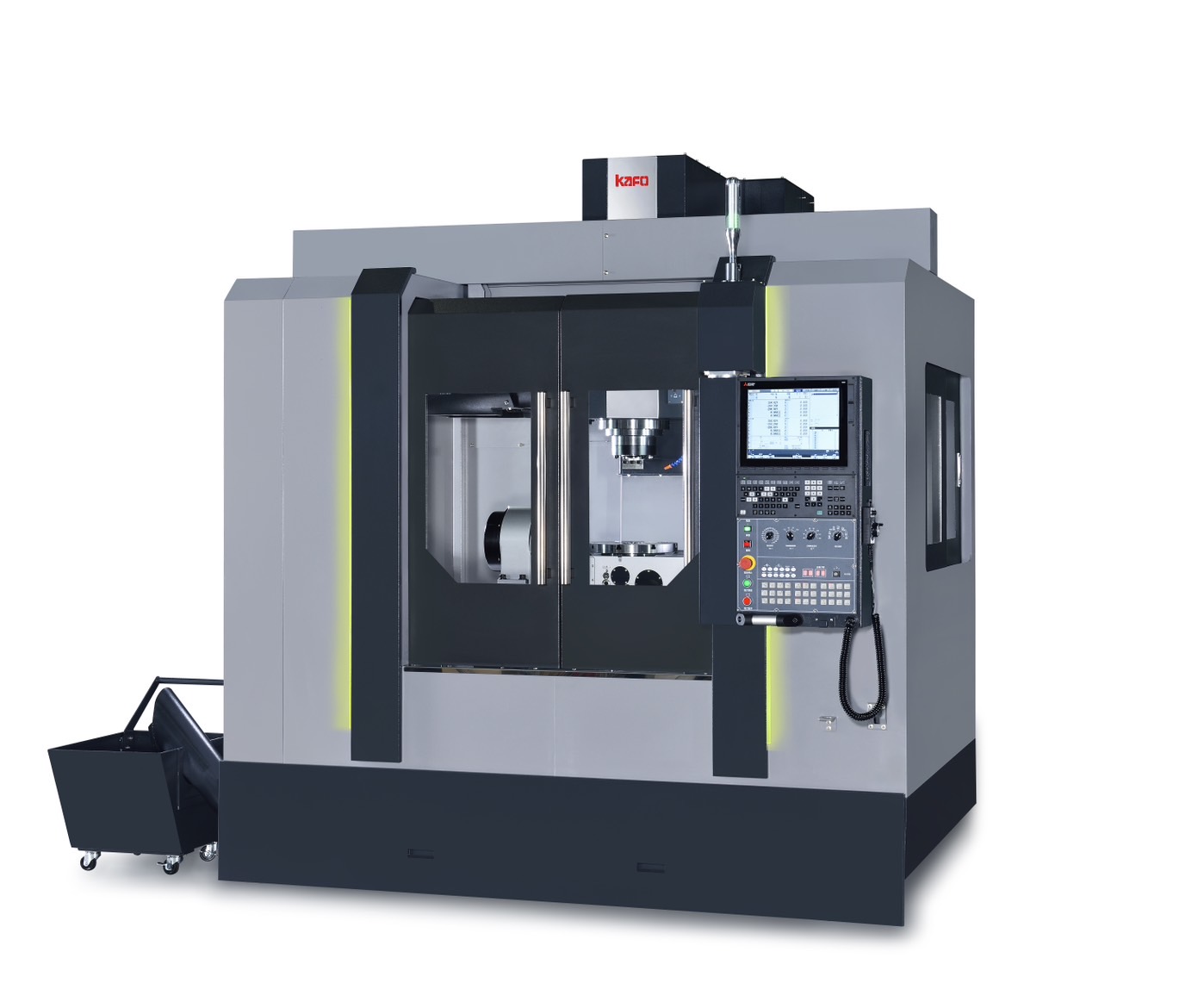

Yongyi Technology has multiple units

Shiyuan vertical integrated processing machine QMC-600

「Shiyuan vertical integrated machining machine QMC-600」

It is a high-performance vertical processing equipment that exhibits advanced design concepts and is specially designed for the mold industry and general metal processing industry. Its strong processing capabilities and precision, as well as high-speed processing capabilities, make it an indispensable part of the modern manufacturing environment.Excellent mechanical structural balance:

The main mechanical structure made of alloy cast iron ensures excellent rigidity and stability. The box-shaped base combined with the pyramid-shaped column structure further enhances the overall rigidity of the machine, effectively reduces vibration and noise, and ensures the stability of high-precision processing.High-speed and high-precision processing capabilities:

Paired with 12,000RPM/15,000RPM high-speed precision spindles, these spindles not only have the advantages of low noise and low thermal displacement, but also maintain excellent machining accuracy under high-speed operation, making them suitable for processing various complex workpieces.Advanced processing technology and control system:

Designed using Shiyuan’s unique high-speed processing technology concept, combined with advanced servo systems and direct-connected spindles, it provides an easy-to-operate and efficient processing environment. The machine is equipped with various series of high-performance CNC controllers, allowing users to easily master various functions of the machine and achieve quick setup and high-precision processing.Competitive prices and comprehensive benefits:

QMC-600 not only has powerful functions and high rigidity, but also stands out with its competitive price. This allows investors to enjoy the substantial benefits brought by high-end processing equipment at a relatively low cost, including significant improvements in production efficiency and stable improvements in product quality.Application scope

“Shiyuan vertical integrated processing machine QMC-600” is suitable for the mold industry and various general metal processing industries, such as precision parts processing, mold manufacturing, aluminum alloy processing, etc. Its excellent performance and efficient processing capabilities can meet the needs of different industries for high-precision and high-efficiency production equipment. Yongyi Technology provides you with QMC-600, an advanced vertical integrated processing machine, which brings excellent technical advantages and great production efficiency, helping you maintain a leading position in the fiercely competitive market.

Lichi vertical integrated processing machine DV -800 / CV -800 / CV -1000

Gaofeng vertical machining center CV-7A (4-axis)

Gaofeng vertical machining center CV-7A (4-axis) is an advanced CNC (numerical control)

processing equipment used by “Yongyi Technology”.

Key features and benefits of this machine include:

1. Four-axis control

Multi-axis machining capabilities:This model has four-axis control capabilities and can perform complex machining actions simultaneously. It is especially useful when processing parts with complex shapes, such as spiral shapes, structures with changing angles, or parts that need to be processed on multiple faces. Improve accuracy and efficiency:

The multi-axis design enables the machine to complete multiple processing operations with one clamping, reducing the number of repositioning workpieces, thereby improving processing accuracy and production efficiency.

2. High rigidity structure

Stable processing platform:Gaofeng vertical machining centers usually have a solid mechanical structure that can provide a high-rigidity and low-vibration processing environment, which helps improve the surface finish and dimensional accuracy of the workpiece. Long term stability:

The sturdy construction and use of high-quality materials enable the machine to maintain stable performance over long periods of operation, reducing the need for maintenance and corrections.

3. High-speed spindle

High speed processing:The CV-7A is equipped with a high-speed spindle that can process at higher speeds, making it suitable for high-precision light cutting and finishing applications. Shorten processing time:

The use of high-speed spindle can significantly shorten the working time of a single piece and improve production efficiency.

4. Advanced control system

CNC technology:The equipment is equipped with an advanced CNC system, which provides precise processing control and automation functions, and can realize complex processing paths and movements. Friendly operation interface:

Modern control panel and human-machine interface (HMI) designs make it easier for operators to set up, operate and monitor the machine.

5. Adapt to diverse materials

Extensive material processing capabilities:The machine is capable of processing a variety of materials, including metals (such as aluminum, steel, stainless steel), plastics and composite materials, adapting to different processing needs.

6. Safety and environmental protection

Safe design:Equipment is usually equipped with a variety of safety features, such as emergency stop switches, protective covers, and robot collision protection systems, to ensure personnel safety during operation. Environmentally friendly features:

Some models are equipped with automatic chip removal and cooling systems, which can effectively handle the waste materials and heat generated during processing and reduce the impact on the environment. In short, Gaofeng vertical machining center The CV-7A (4-axis) provides the advantages of precision machining, increased efficiency, flexibility and versatility, making it an important piece of equipment in advanced manufacturing. The use of Yongyi Technology shows that they value high quality and advanced technology to meet the diverse processing needs of customers.

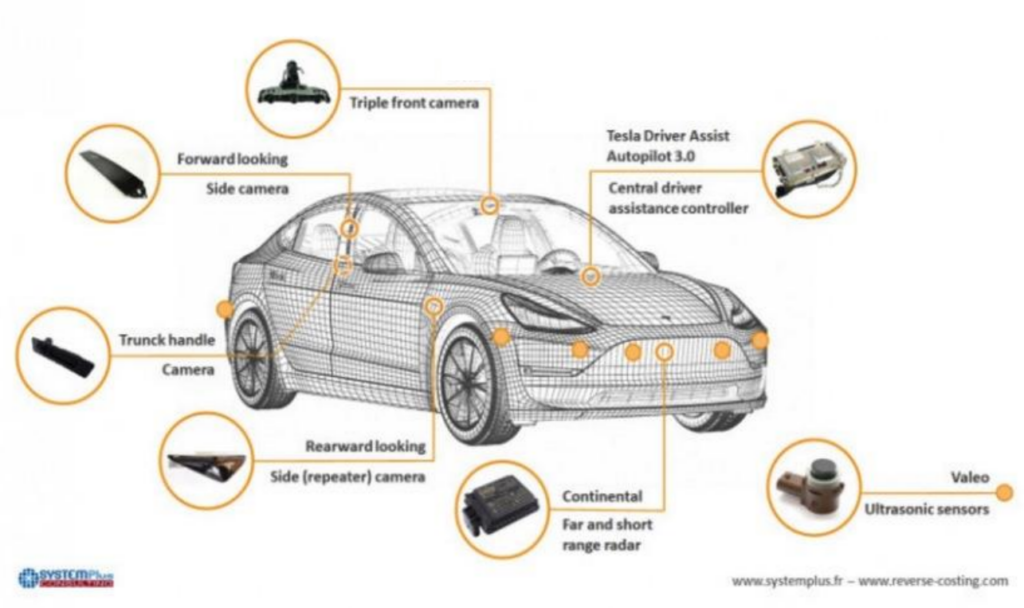

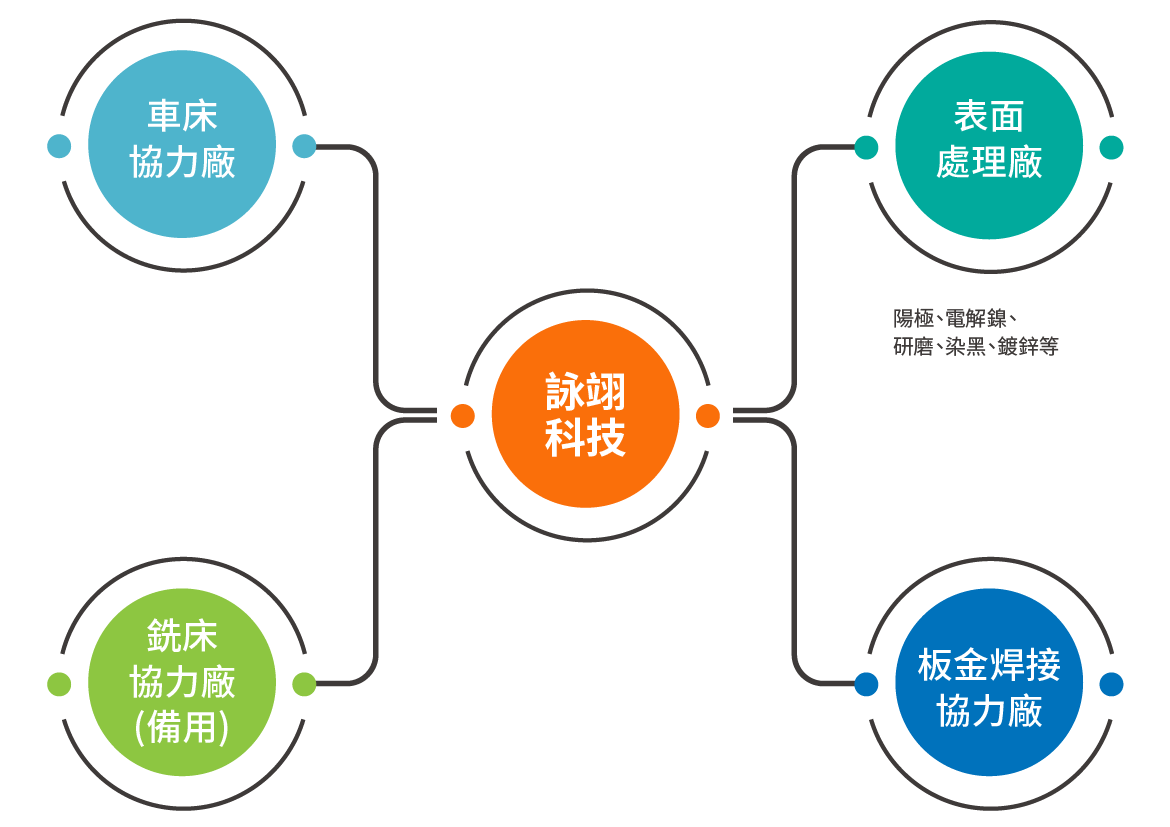

Solve customer problems

Yongyi Technology’s product projects and service scope are very rich, mainly including semiconductor parts processing, automation equipment parts processing, sheet metal welding, automobile parts processing, aerospace parts processing, optical fixture processing, etc. The material classification covers aluminum, steel, stainless steel and engineering plastics, and we provide the entire production process, including material supply, processing, surface treatment, measurement and assembly. In terms of surface treatment, the company can provide anode, nickel electroplating (chemical), grinding, heat treatment, sandblasting, black dyeing, chrome plating and other services.

Professional processing capabilities:

Yongyi Technology has rich processing experience and professional technology, and can accurately manufacture various complex parts, including high-precision parts required in semiconductor components, automation equipment, aerospace and optical fixtures and other fields. Such capabilities can help customers achieve their design and production needs and ensure that product quality and performance meet requirements.

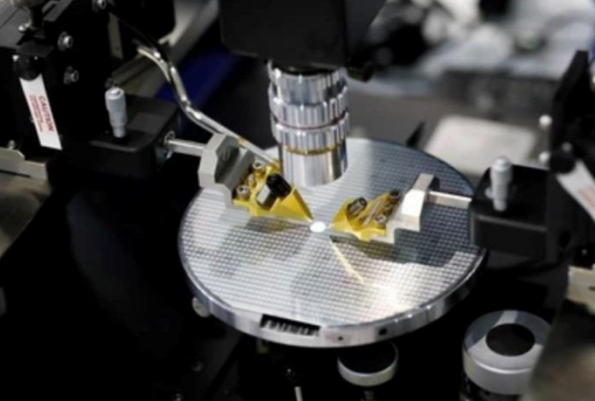

Semiconductor components:

Yongyi Technology has leading professional technology in the field of semiconductor component processing. Semiconductor components usually include various chips, packaging materials, circuit boards, etc. These components are critical to the performance and reliability of electronic products. Yongyi Technology uses advanced manufacturing equipment and technologies, such as precision cutting, laser etching and high-precision measurement systems, to ensure that the processing accuracy of each semiconductor component reaches industry standards. In addition, our team has extensive experience and is able to handle a variety of complex design requirements and technical challenges to meet the needs of different customers.

Semiconductor parts processing:

In terms of semiconductor parts processing, Yongyi Technology provides a full range of processing services, including raw material selection, parts cutting, polishing, and post-processing. Our technology covers processing needs from micron-level precision to nano-level precision, ensuring that each semiconductor part reaches extremely high standards in size, shape and surface finish. Using the latest CNC machining technology and automated production systems, we are able to efficiently and accurately produce large quantities of semiconductor parts while maintaining consistent product quality.

Automated equipment processing:

In the field of automation equipment processing, Yongyi Technology’s professional technology covers the manufacturing of parts for various automation equipment. These equipment usually require extremely high processing accuracy and reliability to ensure efficient operation in the automated process. Our semiconductor component processing technology plays a key role in this, including precision machining, assembly and debugging. We use advanced processing technology to provide high-quality parts for automation equipment, thereby improving the performance and stability of the overall equipment.

Optical fixture processing:

Optical fixtures are key tools for optical testing and adjustment, and Yongyi Technology’s processing technology in this field is equally outstanding. Optical fixtures require extremely high precision and surface finish to ensure accurate alignment and functionality of optical systems. Our semiconductor component processing technology can be used to manufacture various optical fixtures, including lens mounts, optical alignment devices, etc. We use high-precision processing equipment and professional technology to ensure that every detail of the optical fixture can meet strict optical requirements and ensure the performance and stability of the final product.

Aerospace parts processing:

In the field of aerospace parts processing, Yongyi Technology has leading professional technology and can accurately manufacture various complex aerospace parts. The manufacturing of aerospace parts requires extremely high precision and reliability because these parts directly affect the performance and safety of the aircraft. The following are our main expertise in aerospace parts processing:

-

1. High-precision processing technology

Aerospace parts often need to be manufactured within extremely tight tolerances. Yongyi Technology uses advanced CNC machine tools and laser processing technology to achieve micron-level processing accuracy. These high-precision machines can handle complex geometries and minute structures, ensuring every part meets stringent design specifications. -

2. Material handling and selection

Materials for aerospace parts usually include high-strength aluminum alloys, titanium alloys and composite materials. These materials require special processing methods to maintain their strength and toughness. Yongyi Technology has professional material processing technologies, including high-temperature heat treatment, chemical etching and high-pressure waterjet cutting, to cope with the processing challenges of different materials.

Diverse material selection:

The materials provided by the company include aluminum, steel, stainless steel, engineering plastics, etc., which can meet the material needs of different products. This diversity allows customers to select the most suitable material based on the specific requirements of their application, thereby increasing product performance and durability.

Full service:

Yongyi Technology provides full services from material procurement, processing, surface treatment to final assembly. Such a one-stop solution can save customers time and costs and avoid risks and delays caused by multi-party coordination.

High-quality surface treatment:

The company has advanced surface treatment technologies, including anodizing, electroless nickel plating, grinding, heat treatment, sandblasting, black dyeing and chrome plating, etc. These treatments can improve the surface hardness, corrosion resistance and aesthetics of the parts, making the products It can meet customer requirements in appearance and function.

- Semiconductor precision parts 50%

- Automation equipment parts 20%

- Others (auto parts, sheet metal welding…) 25%

- Export to Japan 5%

Advantages

Technical advantages:

With rich processing experience and professional technology, we can solve the manufacturing problems of various complex parts and ensure high precision and high quality of products.

Flexibility and customization

Ability to provide flexible manufacturing solutions, including material selection and surface treatment options, based on customers’ specific needs and design requirements, to achieve optimal product design.

Full-service convenience

Providing one-stop processing and manufacturing services, from raw materials to final product delivery, simplifying customers’ supply chain management and saving time and costs. Quality assurance and reliability: Through strict quality control and inspection procedures, we ensure that products meet customer technical requirements and specifications, providing reliable product performance and long-term use guarantee. All in all, Yongyi Technology, with its rich technical capabilities, diverse material selection and full service advantages, is able to provide customers with high-quality and efficient solutions to meet the manufacturing needs of various industries.

Procurement of materials and post-processing projects

Material → Processing → Surface treatment (anode) → Measurement → Assembly → Shipping

Surface treatment items:

Anode (5 rooms), nickel plating/chemical (3 rooms), grinding (3 rooms), heat treatment (1 room), sandblasting (1 room), black dyeing (2 rooms), chrome plating/galvanizing (2 rooms), Polishing (2 rooms), welding (1 room).

- #CNC Machining – CNC precision turning and milling four-axis component OEM

- #Semiconductor components and automation equipment components supply

- #Stainless steel, aluminum alloy, carbon steel, copper alloy processing

- #Engineering Plastic Processing

- #sheet metal welding

- #ceramic quartz processing

- #Customized project design, manufacturing and development

- #customer assembly service

- #MicroscopeAgent

- # SlideAgent

Operating items·Processing materials

- #Aluminum material – AL 5052 (Japanese plate), AL5083, AL6061 (Korean plate), AL7075, MIC (Alcoa), (China Aluminum)

- #Steel material – S45C, S50C, SS41, SCM440, SKD11, SKD61, SK3, M315

- #Stainless steel material – SUS303, SUS304, SUS316, SUS420, SUS440

- #Engineering plastic material – POM, PEEK, PETP, NC NYLON, PPS, PC transparent, bakelite, acrylic, Teflon

- #ceramic

- #quartz

- #sic