The Critical Role of CNC Precision Machining in Manufacturing Processes and Contract Manufacturing

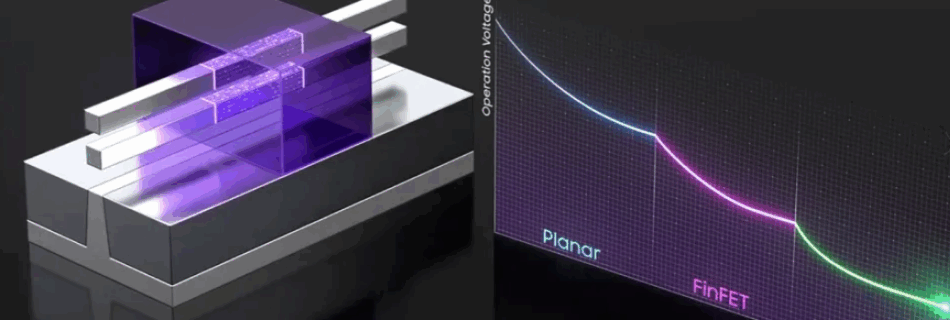

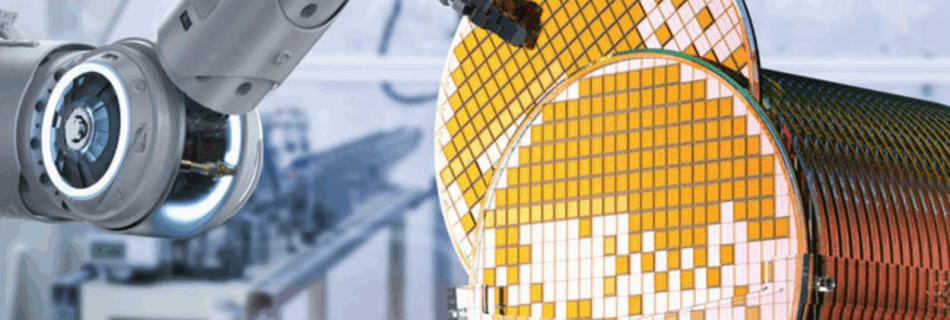

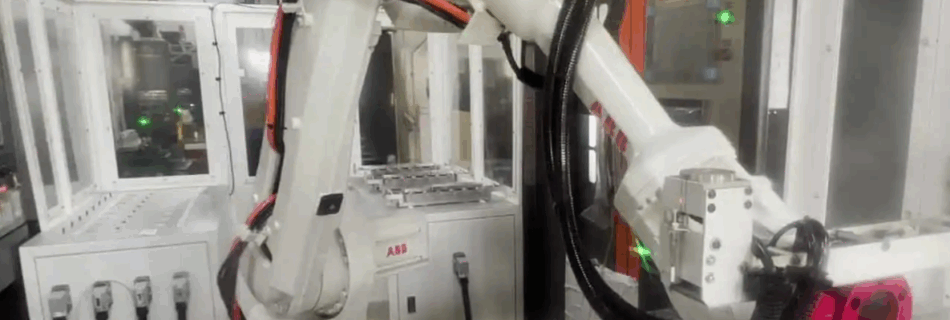

The Critical Role of CNC Precision Machining in Manufacturing Processes and Contract Manufacturing The Era of Silicon Carbide Semiconductors Has Arrived: The Critical Role of CNC Precision Machining in Manufacturing Processes and Contract Manufacturing With the rapid growth of electric vehicles (EVs), renewable energy, AI servers, and high-power semiconductor devices, silicon carbide (SiC) semiconductors have …