In the CNC field, the correct use of measurement tools is critical. These tools are used to inspect and verify whether the dimensions, shapes, and tolerances of machined parts meet design specifications. Below is an introduction to these tools and their applications, particularly in fields such as #CNCmachining, #CNCprecisionmachining, and industries like #semiconductorcomponents, #automationequipment, and #roboticarms that demand high precision.

1. Gear Gauges

Function: Gear gauges are mainly used to measure the module, pitch, or profile of gears.

Applications:

- Module Gear Gauges: Used to determine the module of gears, commonly found in gear transmission systems of #automationequipment or #roboticarms.

- Pitch Gear Gauges: Measure the pitch of gears, especially in machining #precisioncomponents to ensure gear stability during operation.

- Inspection Method: Insert the gauge into the gear teeth groove to check for tight fit without noticeable gaps or looseness.

2. Pin Gauges

Function: Pin gauges are used to check hole diameters, clearances, or other dimensional measurements.

Applications:

- Used in #semiconductorcomponents or #stainlesssteelprocessing to inspect precision hole diameters, ensuring design tolerances (e.g., ±0.02mm) are met.

- Measure tiny holes in #ceramicprocessing components to avoid process deviations affecting performance.

- Operating Method: Insert the pin gauge into the hole and test its fit: the smallest gauge should insert while the largest gauge does not, indicating compliance.

3. Gauge Blocks

Function: Gauge blocks (also known as slip gauges or precision blocks) are high-precision measurement tools used to calibrate other measuring instruments or directly measure part dimensions.

Applications:

- Calibration: Used in #CNCprecisionmachining to calibrate calipers, micrometers, and ensure measurement accuracy.

- Direct Measurement: Measure the height, depth, or thickness of parts made of #engineeringplastics or #stainlesssteel.

- Crucial for inspecting dimensions in #roboticarms structural components to ensure assembly precision.

- Usage Tips: Clean the gauge block and part surfaces to avoid dust or oil affecting measurement accuracy.

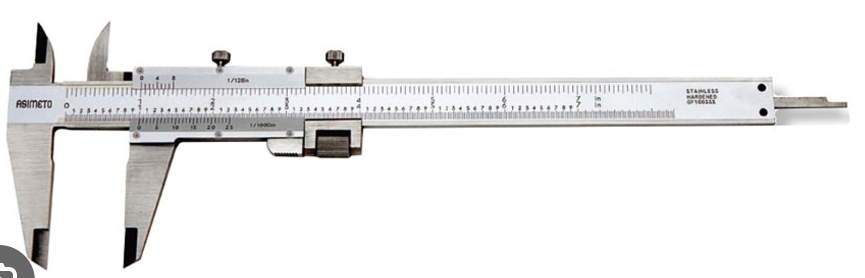

4. Vernier Calipers

Function: Vernier calipers are versatile measurement tools used for measuring internal diameters, external diameters, depths, and step heights.

Applications:

- External Diameter Measurement: Check whether the external diameter of #ceramicprocessing parts meets the standard by reading values on the main scale and vernier scale.

- Internal Diameter Measurement: Measure the precision of holes in #semiconductorcomponents, such as openings in IC modules.

- Depth Measurement: Measure the depth of holes or structural components in #automationequipment.

- Step Measurement: Suitable for checking step designs in #engineeringplastic components, ensuring they meet design specifications.

5. Centicalis (Internal and External Diameter Measurement)

Centicalis is a high-precision measuring instrument, particularly suitable for measuring internal and external diameters in #CNCmachining and #CNCprecisionmachining.

Internal Diameter Measurement:

- Principle: The probe is inserted into the inner hole, expanded to contact the walls, and the value is read, widely used in #semiconductorcomponents and #ceramicprocessing for high-precision measurements.

- Applications: For measuring tolerances of bearing holes or cylinder inner walls, ensuring products meet ultra-high precision requirements.

External Diameter Measurement:

- Principle: The probe surrounds the part’s external diameter, adjusted to stable contact, and the reading is taken.

- Applications: Widely used in inspecting external diameters of #stainlesssteelprocessing components or #roboticarm joint parts.

Usage Recommendations:

- Accurate Calibration: Ensure tools are calibrated and undamaged before measurement, especially in #CNCmachining and #CNCprecisionmachining processes.

- Clean and Maintain: Keep tools and part surfaces clean, particularly when measuring #ceramicprocessing or #engineeringplastic components, to avoid oil or dust affecting precision.

- Avoid Excessive Force: Apply moderate force during measurement to prevent tool damage or inaccurate data.

- Record Data: Compare measurement results with design specifications for quality tracking of #semiconductorcomponents or #automationequipment parts.

The correct use of these tools ensures the quality and precision of #precisioncomponents manufacturing, greatly enhancing production efficiency and reducing defect rates, forming a cornerstone in the #CNCmachining industry.

#CNCmachining, #CNCprecisionmachining, #semiconductorcomponents, #automationequipment, #precisioncomponents, #roboticarms, #stainlesssteelprocessing, #engineeringplastics, #ceramicprocessing

#GearGauges #Centicalis #PinGauges #GaugeBlocks