Stainless Steel Matte Finish: A Comprehensive Guide to Surface Treatments

There are various surface treatment methods for stainless steel. Today, we will introduce the most commonly used SUS 304 stainless steel material by Zhengyan Company and explore four widely used stainless steel surface treatment techniques.

2B Stainless Steel Matte Finish

Applications: Stainless steel inner tanks, customized product interiors

2B stainless steel matte material undergoes cold rolling, heat treatment, and acid pickling to achieve a uniform matte finish. This type of stainless steel offers good brightness at an economical cost, making it widely used for internal structures, such as stainless steel inner tanks and customized product interiors. This treatment does not affect the exterior appearance while balancing cost and durability. #StainlessSteelMatteFinish

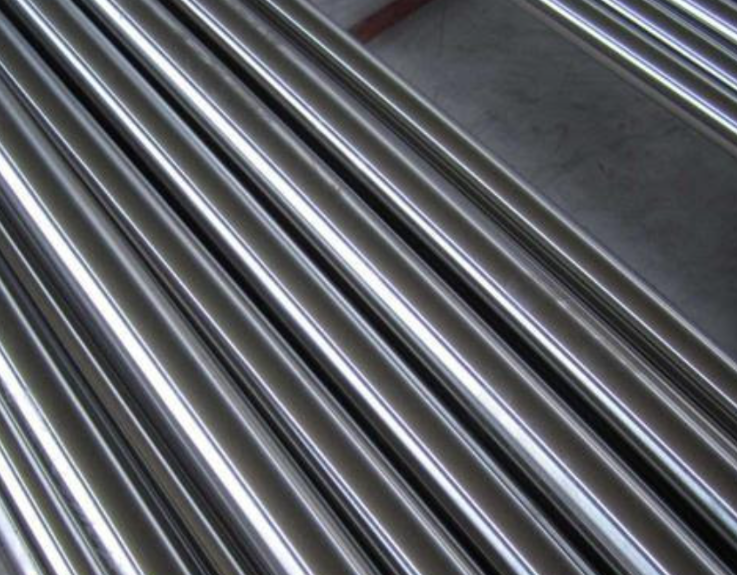

HL Stainless Steel Hairline Finish

Applications: Trash cans, carts, customized stainless steel products

HL (Hairline) stainless steel undergoes fine grinding to create continuous, delicate linear textures, giving it a premium aesthetic. This treatment is not only visually appealing but also highly wear-resistant, with scratches being less noticeable. It is widely applied in trash cans, carts, and other products. Zhengyan Stainless Steel’s HL matte finish is a top choice due to its durability and modern appearance. #CNCMachining

BA Stainless Steel Bright Finish

Applications: Sinks, mailboxes, fences, tables, and other smooth surface products

BA (Bright Annealed) stainless steel undergoes cold rolling and bright annealing to achieve a mirror-like smooth surface. It is suitable for high-end decorative applications, such as kitchenware, home appliances, sinks, mailboxes, and tables. This treatment not only enhances the product’s aesthetics but also improves corrosion resistance.

Mirror Stainless Steel Finish

Applications: Architectural decorations, elevators, escalators, signage, flower pots, etc.

Mirror stainless steel is finely polished to create a high-reflective effect like a mirror, making it ideal for architectural decorations, elevators, escalators, signage, and flower pots that require a high-end visual effect. If customers have specific requirements, Zhengyan Company provides customized mirror stainless steel products to meet various decorative needs.

Zhengyan Stainless Steel Quality Assurance

As a professional manufacturer of stainless steel trash cans and customized products, Zhengyan Stainless Steel is committed to delivering high-quality products, ensuring that every detail meets customer expectations.

Throughout the communication and production process, we work closely with users, procurement departments, and maintenance teams to provide the best solutions. For instance, we offer competitive pricing while tailoring products to meet functional requirements. Additionally, we provide guidance on maintenance and cleaning methods to ensure durability, minimizing unnecessary repairs and costs.

Customer First, Mission Accomplished

From custom design to manufacturing and delivery, Zhengyan Stainless Steel prioritizes customer needs. Even if last-minute changes occur before delivery, such as adding stainless steel accessories or reinforcing components, we will make every effort to provide the best solution, ensuring customer satisfaction.