In CNC Machining and Related Fields, What Are “Anodizing,” “Electroplated Nickel / Chemical Nickel,” “Grinding,” and “Heat Treatment”?

In CNC Machining and Related Fields, What Is “Anodizing”?

In CNC machining and related fields, “anodizing” typically refers to the electrochemical process of anodizing. This process is primarily used for aluminum and its alloys, aiming to improve corrosion resistance and hardness by forming a layer of aluminum oxide (Al₂O₃) on the surface of the aluminum.

During the anodizing process, aluminum parts serve as the anode placed in an electrolyte solution, and an electric current causes the aluminum surface to oxidize. This oxide layer not only provides protection but also allows for further coloring and decorative treatments, enhancing appearance.

This technique is widely used in industries such as aerospace, automotive, and electronics, as it significantly enhances material performance and longevity.

In CNC Machining and Related Fields, What Are “Electroplated Nickel / Chemical Nickel”?

In CNC machining and surface treatment fields, “electroplated nickel” and “chemical nickel” are techniques used to enhance the surface properties of metals.

Electroplated Nickel

Electroplated nickel is a method of depositing nickel metal onto a substrate surface via electric current. This treatment enhances the metal’s corrosion resistance, wear resistance, and appearance. The electroplating process typically occurs in an electrolyte solution, allowing control over the thickness and uniformity of the plating.

Chemical Nickel

Chemical nickel is a current-free deposition process. In this method, nickel is deposited onto the metal surface through a chemical reaction, forming a uniform coating. The advantage of chemical nickel plating lies in its ability to create an even coating on complex shapes without the need for electrical current, usually exhibiting good corrosion and wear resistance.

Both techniques are widely applied to enhance the performance of components, especially in industries such as aerospace, automotive, and electronics.

In CNC Machining and Related Fields, What Is “Grinding”?

In the field of CNC machining, “grinding” is a processing method used to enhance the surface smoothness and precision of workpieces. This process typically involves the use of grinding tools or abrasives to remove material through friction, achieving the desired surface finish.

Types of Grinding

- Flat Grinding: Used for processing flat surfaces, usually with a surface grinder.

- External Cylindrical Grinding: Used for processing the outer cylindrical surfaces, typically with an external cylindrical grinder.

- Internal Cylindrical Grinding: Used for processing internal cylindrical surfaces, usually with an internal cylindrical grinder.

- Ultra-precision Grinding: Used for applications requiring extremely high precision and smoothness, commonly for optical components and precision machinery.

Advantages of Grinding

- Improves Surface Finish: Can achieve very high smoothness, suitable for precision parts.

- Precise Dimensional Control: Capable of achieving high precision in dimensional control.

- Removes Stress: Can help eliminate internal stresses generated during the machining process.

Grinding plays a significant role in industries such as aerospace, automotive, and mold manufacturing, especially in applications requiring high precision and surface quality.

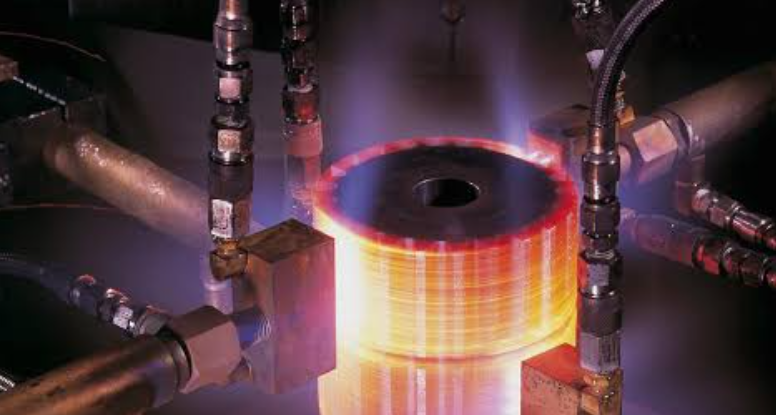

In CNC Machining and Related Fields, What Is “Heat Treatment”?

In CNC machining, “heat treatment” is a process of altering the internal structure and properties of metal materials through heating and cooling. Heat treatment can improve characteristics such as hardness, strength, toughness, and wear resistance, thereby meeting specific application requirements.

Common Types of Heat Treatment

- Annealing: Heating the material to a certain temperature followed by slow cooling to reduce hardness, increase toughness, and decrease internal stress.

- Quenching: Heating the material to high temperatures and then rapidly cooling (typically in water or oil) to increase hardness, though it may become brittle.

- Tempering: After quenching, heating the material to a lower temperature and then slowly cooling to improve toughness and reduce brittleness.

- Normalizing: Heating the material to above the critical temperature and cooling in air to achieve a uniform structure, enhancing mechanical properties.

Advantages of Heat Treatment

- Improves Performance: Heat treatment can significantly enhance the mechanical properties of materials, adapting them to various usage requirements.

- Reduces Internal Stress: Effectively eliminates internal stresses generated during processing, reducing the risk of deformation.

- Extends Service Life: By improving wear resistance and strength, it prolongs the service life of workpieces.

Heat treatment plays a critical role in industries such as aerospace, automotive, and mold and tool manufacturing, being a key step in ensuring product performance and reliability.