The rise of CNC machining technology marks an important milestone in industrial development. In the past, many manufacturing processes relied on manual operations for measuring, cutting, and engraving. These workflows were not only time-consuming but also susceptible to human error, leading to instability in precision and consistency.

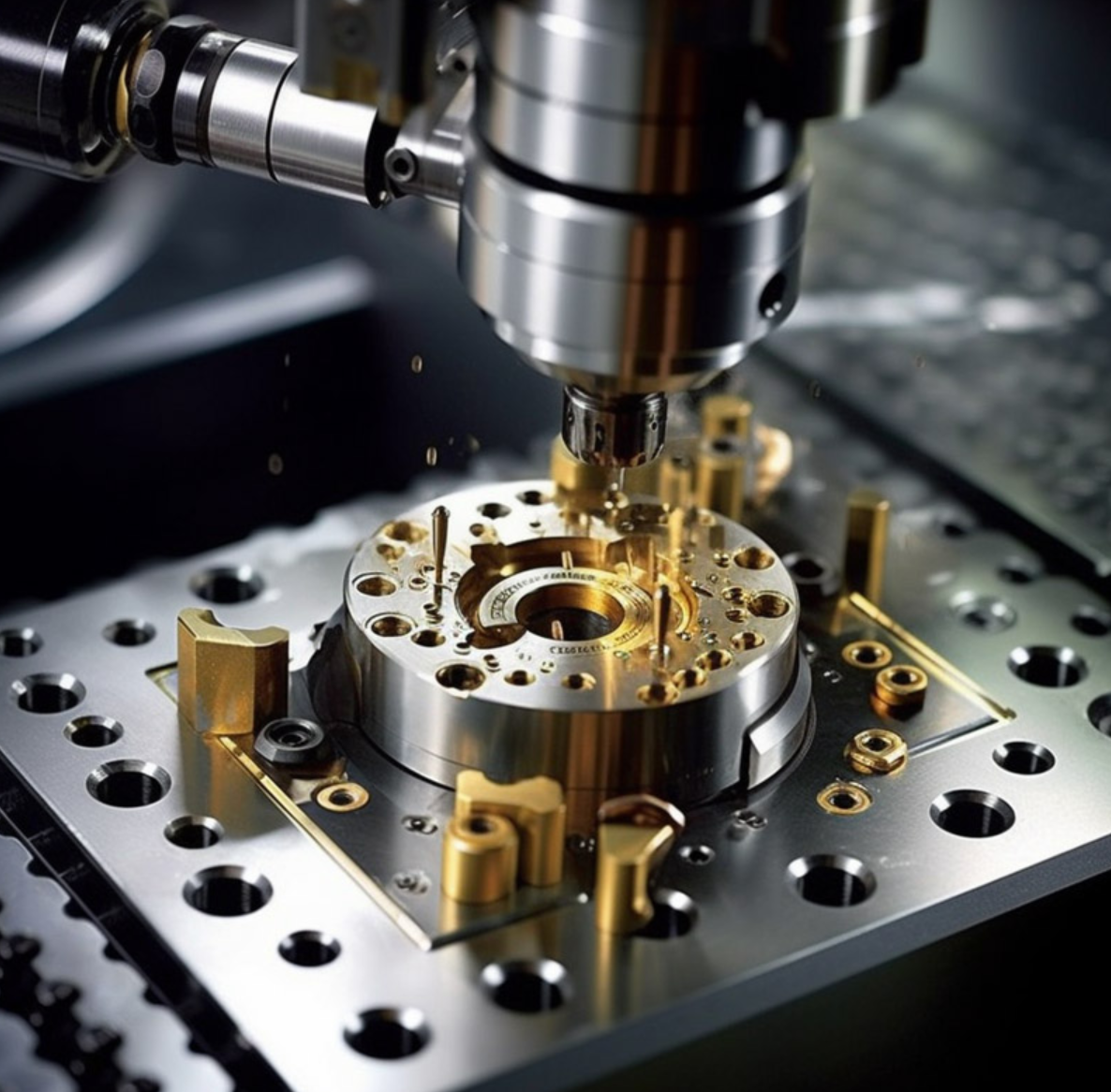

With the introduction of CNC machining technology, a fundamental change has occurred. The CNC (Computer Numerical Control) system enables machinery to automatically execute precise operations without extensive manual intervention. This not only increases production speed but also significantly enhances machining accuracy, meeting increasingly high product demands.

Today, CNC machining technology is widely used across various industries, achieving the ideal of automated production and greatly enhancing manufacturing efficiency and product quality. This transformation not only represents progress in industrial technology but also lays the foundation for the future of manufacturing.

CNC machining (Computer Numerical Control machining) is a technology that uses computer-controlled machinery to carry out precise manufacturing. CNC stands for “Computer Numerical Control.”

How it works:

- Design Phase: First, designers create a 3D model of the part using CAD (Computer-Aided Design) software.

- Conversion to G-code: Once the design is complete, the CAD model is converted to G-code, which is a command language that tells the CNC machine how to move.

- Setting up the Machine: The operator places the raw materials needed for processing on the CNC machine and ensures the machine’s tools and settings are correct.

- Machining Process: The machine automatically performs cutting, drilling, engraving, and other operations according to the G-code instructions, precisely creating the required parts.

Functions:

- High Precision: CNC machining can achieve extremely high manufacturing precision, suitable for parts with strict requirements.

- Automation: Significantly reduces manual operations, improving production efficiency.

- Complex Shape Machining: Capable of processing complex geometries to meet various design needs.

- Consistency: In mass production, the quality and dimensional consistency of each part are high.

CNC machining operates differently across various industries such as aerospace, automotive, medical, and electronics. Below are specific applications and operational methods for each industry:

1. Aerospace

- Precision Parts Manufacturing: Aerospace requires high-strength, lightweight materials, and CNC machining can precisely manufacture critical components like wings and engine parts.

- Multi-material Machining: Capable of processing complex materials such as titanium and aluminum alloys to ensure compliance with stringent safety standards.

- Automated Inspection: Many CNC machines are equipped with automated inspection systems to guarantee the precision and consistency of parts.

2. Automotive

- Mold and Component Manufacturing: CNC technology is used to produce automotive molds and various components, such as hoods and body panels.

- Rapid Prototyping: Quickly creates prototypes to assist design teams in testing and validating designs.

- Mass Production: Enables large-scale automated production, increasing efficiency and reducing costs.

3. Medical

- Medical Devices: CNC machining is used to produce surgical tools, prosthetics, implants, and other precision medical devices.

- Personalized Manufacturing: Can customize production based on specific patient needs, such as prosthetics tailored for individual patients.

- Material Diversity: Utilizes biocompatible materials to ensure the safety and effectiveness of medical devices.

4. Electronics

- Circuit Board Machining: CNC technology is used to manufacture printed circuit boards (PCBs), ensuring precise cutting of circuits.

- Casing and Components: Used to produce housings, heat sinks, and other components for electronic products, enhancing overall performance.

- Small Batch Production: Supports small batch customization and rapid iteration to adapt to rapidly changing market demands.

The core advantages of CNC machining lie in high precision, automation, and flexibility, enabling it to effectively respond to various complex manufacturing needs and play a critical role across different industries.

Yong Yi Technology’s important position in the CNC machining field stems from its twenty years of professional experience and outstanding technical capabilities. The company understands the stringent requirements for machining precision and quality across various industries and provides high-quality CNC milling services tailored to meet diverse customer needs.

1. Professional Technology

Yong Yi Technology has an experienced professional team familiar with various materials and machining techniques, capable of handling a wide range of parts from simple to complex. This enables them to provide customized solutions for industries such as aerospace, automotive, medical, and electronics.

2. High-Quality Standards

Yong Yi Technology adheres to a strict quality management system, ensuring that each machined part meets high-quality standards. They utilize advanced CNC equipment in combination with meticulous processes to achieve high precision and consistency in their products.

3. Customer Orientation

Yong Yi Technology emphasizes communication and collaboration with customers, providing flexible solutions based on specific needs. This customer-centric service philosophy has earned them a good reputation in the market.

4. Innovation Capability

Yong Yi Technology continually invests resources in technological research and development and equipment upgrades to maintain its competitive edge. Their innovations in CNC machining technology help customers better adapt to market changes and enhance product competitiveness.

5. Market Trust

With outstanding machining technology and quality service, Yong Yi Technology has established a good reputation in the industry and has become a partner for several well-known companies. This not only solidifies its position in the market but also lays a solid foundation for future expansion.

In summary, Yong Yi Technology, with its professional experience, high-quality standards, customer orientation, innovation capability, and market trust, has become an important player in the CNC machining field, providing stable support and services to multiple industries.

Computer Numerical Control